Main Features

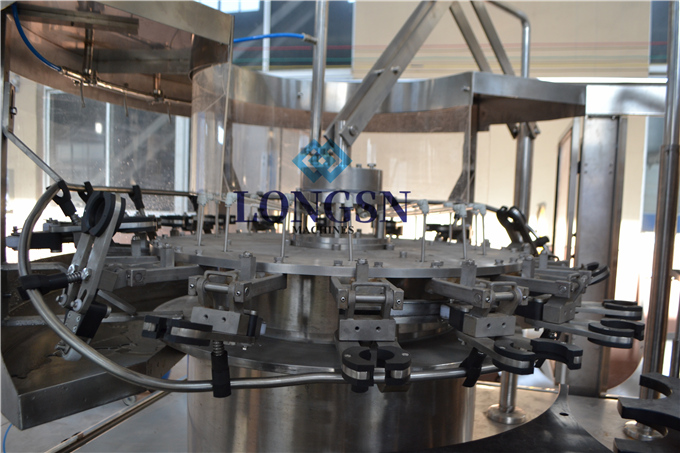

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

Technical parameters:

|

Model |

CGF14-12-5 |

CGF18-18-6 |

CGF24-24-8 |

CGF32-32-10 |

CGF40-40-12 |

CGF50-50-15 |

|

|

Rising heads |

14 |

18 |

24 |

32 |

40 |

50 |

|

|

Filling heads |

12 |

18 |

24 |

32 |

40 |

50 |

|

|

Capping heads |

5 |

6 |

8 |

10 |

12 |

15 |

|

|

Capacity based on 500ml PET bottle |

4000-5000BPH |

6000-7000BPH |

10000-12000BPH |

13000-15000BPH |

20000-24000BPH |

30000BPH |

|

|

Suitable bottle shape |

PET bottles with different volume and shapes |

||||||

|

Suitable bottle diameter(mm) |

Φ50-115 |

||||||

|

Suitable bottle height |

160-320mm |

||||||

|

Compressed air pressure |

0.3-0.7MPa |

||||||

|

Washing water pressure |

>0.06MPa,≤0.2MPa |

||||||

|

Motor power (KW) |

2.2 |

3.5 |

4.5 |

6.0 |

7.5 |

9.5 |

|

|

Dimensions(mm) |

2400*1650*2500 |

2600*1920*2550 |

3100*2300*2800 |

3800*2800*2900 |

4600*2800*2900 |

5450*3300*2900 |

|

|

Weight (KG) |

2500 |

3500 |

4500 |

5600 |

8500 |

9800 |

|

What service can offer you ?

1. 24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

2. Two Years guarantee

3. Your business relationship with us will be confidential to any third party.

4. Good after-sle service offered, please get back to us if you got any questions.

You may have questions as follow :

1. How about the spare parts?

We will send one year enough easy broken spare parts together with the machines, shipping together.During the warranty time, we will supply the spare parts, and the we will responsible the delivery charge.

2. How long for installation?

According your machines order, we will send one or two experienced engineers to your factory to help installation and training. It will take about 7 days to 15 days.

3. How to install my machine when it is arrives? How much the installation cost?

We will send our engineers to your factory to help install the machines and train your staff how to operate the machines.Customers pay round - air tickets, accommodation and USD100 per day per person.

4. When can I get my machines after I paid?

Normally production time is around 35-75 days, the exactly depend on what kinds of machine you ordered. The shipping time is based on your destination port.

5. What is your guarantee or the warranty of the quality if we buy machine from you?

We offer high quality machines to you with 2 year guarantee with 2 years free spare parts and supply life-long technical support.

6. Are you a trading company or manufacturer?

We are a manufacturer, we supply the factory prices goods and with good quality, welcome to visit!